Powder feedstock evaluation for additive manufacturing

Objective:

Research quality assessment standards for metal powders used in additive manufacturing

Problem:

- Powder feedstock assessment is essential for certification of powders received from suppliers and for qualification of powders reused in Powder Bed Fusion (PBF) processes.

- Attention has been paid to the test methods required to measure the key powder properties to assess powders, however there are no guidelines indicating what is deemed an acceptable test result. This information is needed to guide users of metal powders on when to accept powder batches from suppliers, when to refresh recycled powders and when to quarantine powder batches.

Impact:

- This project addresses the following gaps in the AMSC roadmap

- Gap PM1: Flowability

- Gap PM2: Spreadability

- Gap PM3: Particle Size and Particle Size Distribution

- Gap PM4: Particle Morphology

- Gap PM7: AM Process-Specific Metal Powder Specifications

Solution:

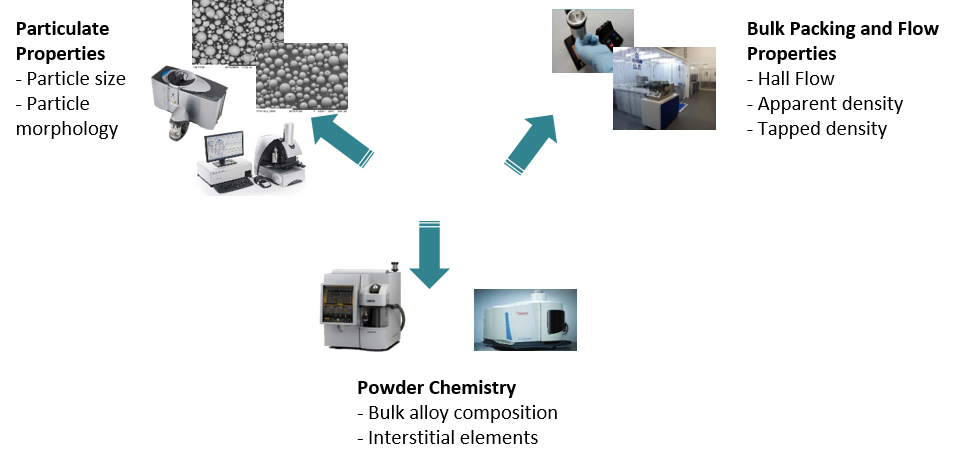

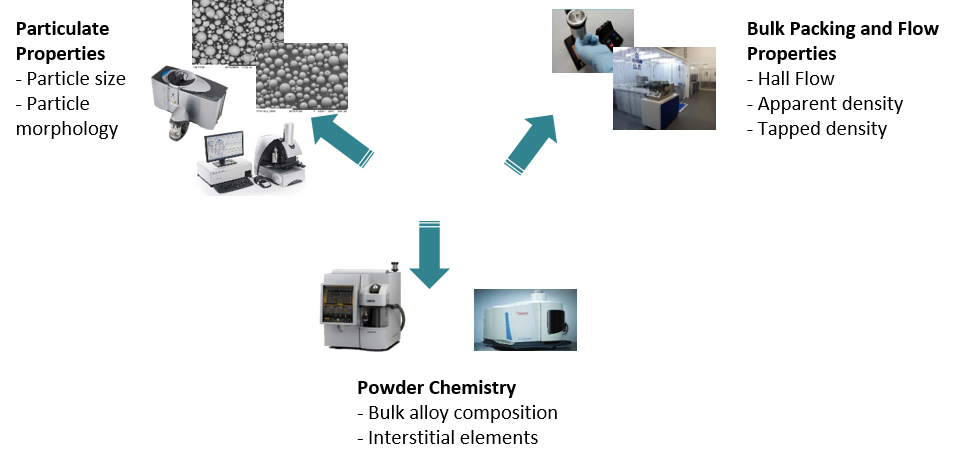

- Evaluation of key powder properties and ASTM powder test methods. The focus was to test methods covered by current ASTM methods (e.g. those shown in Figure 1), with the intention of expanding this study to test methods not covered by ASTM standards in future work.

- An operator proficiency study was performed to obtain typical repeatability in ASTM standard test methods for AM powders. Data from ASTM’s AM Proficiency Test Programme (PTP) was leveraged to provide inter-laboratory test data.

- Best practice guidance was given on powder test methods to make them more suitable for AM powders, and guidance on test method selection and suitability of test methods to AM processes was also provided.

Output:

- WK66030 - Standard Guide for Quality Assessment of Metal Powder Feedstock Characterization Data for Additive Manufacturing (AM)

Figure 1: Powder test methods