Oct 2017 – Mar 2019

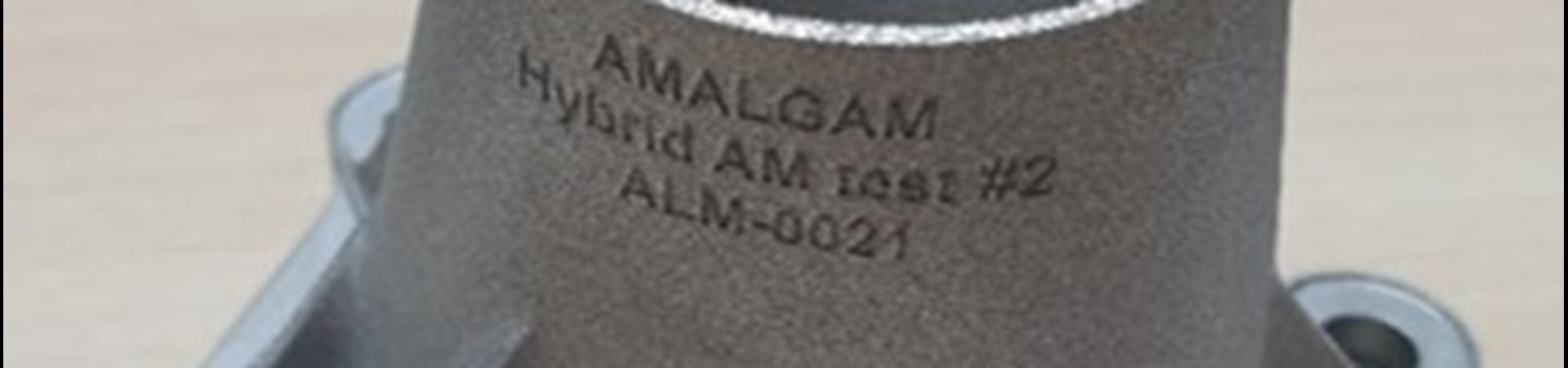

The aim of the AMALGAM project was to develop and demonstrate a revolutionary approach to the design and manufacture of compound boosting systems, leading to improved engine efficiency and lower CO2 emissions. The new approach combined the latest hybrid laser cladding and 5-axis machining AM approach with parts produced by metal powder bed fusion AM and conventional manufacturing in a single “join as you make” operation.

This provided a cost effective, efficient and flexible method of producing high performance automotive parts, using the optimum combination of processes. The AMALGAM approach enabled novel part design and material combinations to be used to have a dramatic impact on performance. The new approach is not restricted to boosting systems but can be used in a wide range applications in motorsport, low volume and mainstream vehicles, as well as the wider high volume manufacturing sector.

Enables the ideal combination of manufacturing processes (powder bed AM, directed energy deposition AM and machining) to be used to make a complex high performance part.