The NCAM runs many projects for industry and most of these are confidential and not shareable as case studies. Details from some projects are shareable which are included on this page.

See also the summaries of our collaborative projects and member-based core research programme.

Using the NCAM’s Metal Powder Bed Fusion facility, the MTC conducted a discovery project focussed on identifying and assessing opportunities to reduce the carbon footprint of the metal AM process chai…

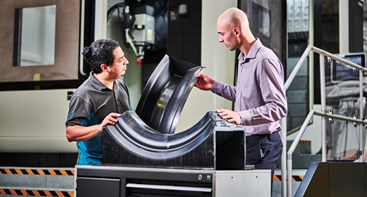

Working with Hybrid Manufacturing Technologies Ltd., MTC used a large flow rate polymer extrusion head integrated with a CNC machine to produce an autoclave composite tooling.

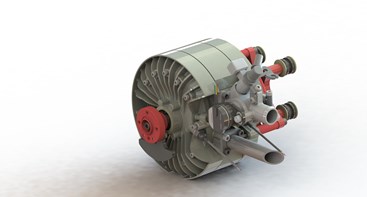

Current hydraulic systems rely on 20th century designs that are only 20% efficient. Domin is developing stateof-the-art technology which increases the efficiency of all systems by 400%. They are disru…

Rolls-Royce and the MTC collaboratively designed, set-up, and operated an additive manufacturing pre-production facility that supplied all of the titanium Engine Section Stator (ESS) components requir…

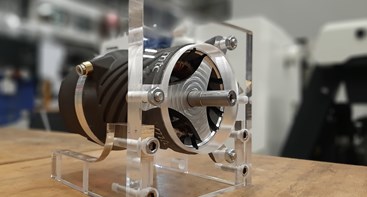

Investigating the state of the art to determine current constraints and development opportunities of additive manufacturing for electric motor components.

A gas turbine engine emissions rake with multiple sensors was re-engineered, by creating complex internal channels, to consolidate several components into a single part and to evaluate the Autodesk Ne…

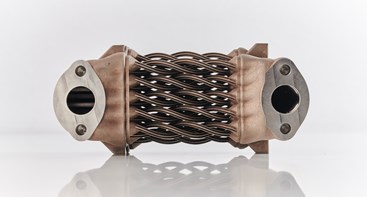

The tube component of a single pass shell and tube heat exchanger was re-designed to utilise the geometrical complexity enabled by AM resulting in the consolidation of a ~40 part assembly into one com…

AE Aerospace specialises in machining difficult-to-make precision metallic parts, chiefly in the Aerospace, Marine & Defence mechanical or fluid power systems. Although AE is nominally a make-to-print…

Arrowsmith Engineering has built a strong reputation as a supplier of high precision machined parts in the aerospace, military and energy industries. In aerospace, it supplies parts to Tier 1 companie…

Operating from a state-of-the-art facility in Pinxton, Nottinghamshire, Nasmyth Bulwell specialises in the manufacture of precision parts, kits, airframe assemblies and sub-assemblies using the latest…

Gardner Aerospace is a leading international manufacturer of aerospace finished components, comprising simple to highly complex and small to very large machined and sheet metal fabricated detailed par…

Rotite Technologies Ltd is an industrial technology business with a unique and globally patented technology. They are focused on developing advanced fasteners and connectors for customers in the aeros…

Meggitt PLC is a leading international company specialising in high performance components and subsystems for the aerospace, defence and selected energy markets. They consistently deliver solutions fo…

Advanced Innovative Engineering (AIE) are the latest incarnation of a development, design and manufacturing heritage that stretches back to Norton in the 1960s and beyond. Their combined 80 year’s exp…

Swiftool Precision Engineering Ltd (SPE) is part of the SPE Group and is a first choice vendor to a global customer base supplying safety critical parts to the nuclear, petrochemical, aerospace and mo…

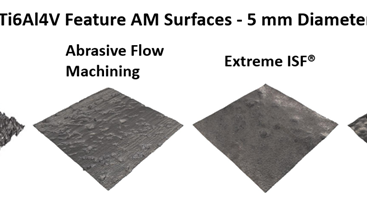

The MTC assessed the capability of various techniques to finish a variety of internal features in AM parts, both through experimental trials and a literature review. Further to this, the MTC developed…

Domin are seeking to revolutionise the fluid power industry and save a billion tonnes of CO2 per year by 2030. One of the key enablers for this is a low cost, high volume additive manufacturing proces…

Part of the Hyde Group of companies, Hyde Aero Products (HAP) is one of Europe’s leading aerospace engineering service providers, specialising in design and manufacturing solutions. The company has re…

Glenair contacted the DRAMA program as it was experiencing rapid growth and was keen to understand whether metal AM would help secure early customer engagement and compress product development respons…

The MTC, in partnership with the award winning Oxford Brookes Formula Student team, has used Additive Manufacturing (AM) to produce titanium uprights giving a 50% weight saving. The motorsport car des…

Additive manufacturing (AM) uses powder as its raw material feedstock. It is known that the powder characteristics will impact on the quality of the final AM components. Historically characterisation…

The MTC, working with the HVM Catapult, used ground-breaking manufacturing capabilities to improve the performance of a Paralympic Sit Ski. By using the Sit Ski as a demonstrator, the HVMC could showc…

Horizon 2020 Clean Sky 2 is an ongoing project that aims to evaluate the maturity of Additive Manufacturing (AM) for future use in safety critical aerospace applications. This is to be achieved throug…

The MTC worked with GRM and K-Tech on a project to investigate the weight-saving of an additive manufactured motorbike part.

The MTC, in partnership with Assystem has demonstrated the capability of using Additive Manufacturing (AM) to enable 30% weight savings for aircraft seat structures.

The MTC helps TTI develop a phased implementation plan to create a fully functional manufacturing facility to supply high value components produced by advanced powder metallurgy techniques.

The MTC works with Rolls-Royce on the additive manufacture of a flight test front bearing housing, resulting in 30% improvement in lead time for first part to stores for the engine development program…

The MTC provides additive manufacturing expertise to help space R&D company Magna Parva develop a crushable thermal protection system for the Mars Return Capsule.

The MTC works in collaboration with Skanska, Foster + Partners, Tarmac, ABB, and Loughborough University to develop a 3D concrete printing system for industrial applications.

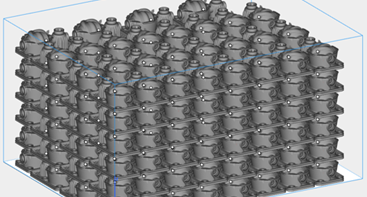

The MTC partner with Betatype to demonstrate a new design workflow that is up to eight times faster for the creation of highly complex additive lattice structures