The National Centre for Additive Manufacturing has several workshops that house our Additive Manufacturing and downstream processing equipment. These facilities are industrial-scale and provide representative test-beds for development work. They are also digitally connected enabling data to be captured from the process chain stages and used to optimise the processing.

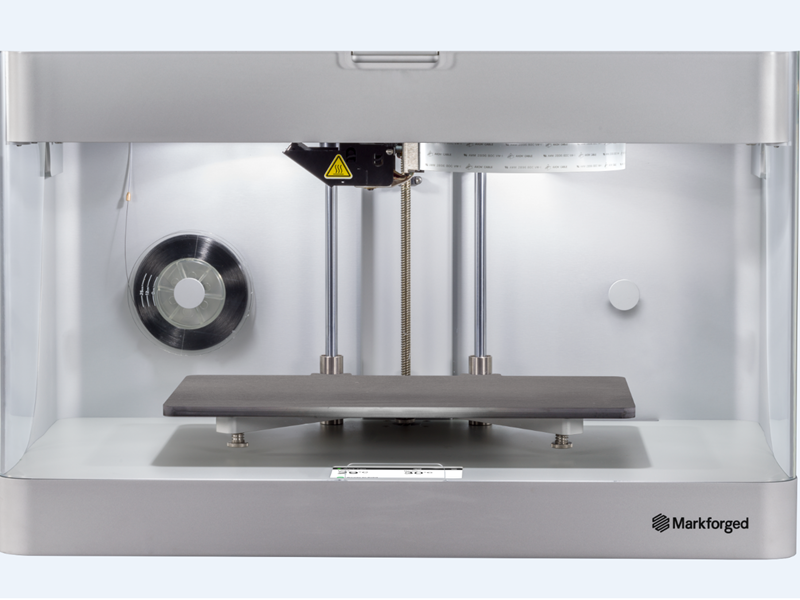

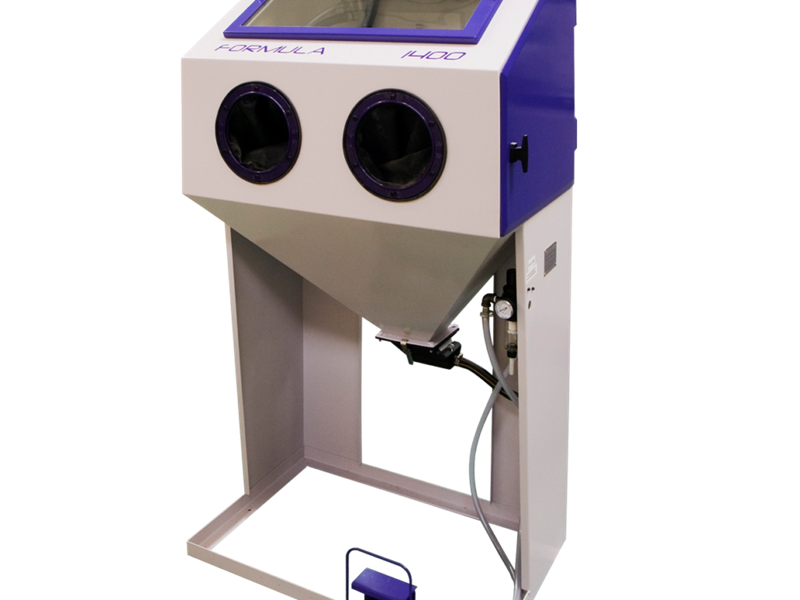

Our Additive Manufacturing capabilities span the following types: metal powder bed fusion, polymer, ceramic and metal bind & sinter technologies and associated post-processing equipment (more details below).

We are constantly improving and adding to our capabilities, whether it’s new machinery or adding novel materials. If you can’t find a suitable process or material for your requirement please get in contact with us via the “Contact” page to see how we can help. We are also familiar with other capabilities, particularly in the UK, and can coordinate or signpost you to other facilities that have equipment we don't.