|

CRP year |

2013 |

|

Budget |

£45k |

|

Project Reference No. |

30233 |

|

Technical Lead |

Jason Dawes |

|

AM process & materials used |

Focused on metal powder bed fusion literature review material independent, specific recycling studies on Ti6/4 and Steel 15-5. |

This project investigated the current industrial and academic understanding of the effect of continuous reuse of metallic powder in powder bed fusion additive manufacturing (AM). The project consisted of three work packages.

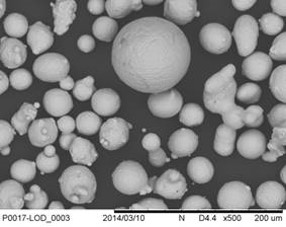

1. The first work package explored the scientific literature on metallic powder recycling. The major findings of the report indicated that, at the time, there was limited scientific study on the effect of powder recycling and that there had been limited application of advanced powder characterization techniques to understand the nature and quality of metal powders.

2. Based on the findings of the literature review an experimental methodology was proposed to investigate the degradation of powder quality as a result of continuous reuse in AM. Two alloy types were analysed – stainless steel 15-5 and Ti6Al4V. There was a common observation across both powder types that on continuous reuse there was a small change in particle size distribution due to loss of fines, this was seen to have a beneficial effect on flow tests such as the Hall flow. In addition, the interstitial elements, particularly oxygen, were seen to increase on continuous reuse.

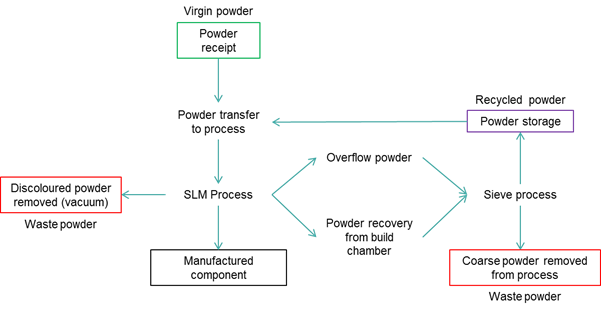

3. The final work package investigated two AM processing facilities. For each facility, a review of the current powder handling processes was conducted to investigate the potential areas for interstitial or foreign particulate pick-up. The main areas of concern highlighted were the open-air powder handling processes and the fact that AM machines are rarely used exclusively for a particular alloy type.

If you are a member you can access the deliverables of this project here.