|

CRP year |

2017 |

|

Budget |

£115k |

|

Project Reference No. |

32299 |

|

Technical Lead |

Bochuan Liu |

|

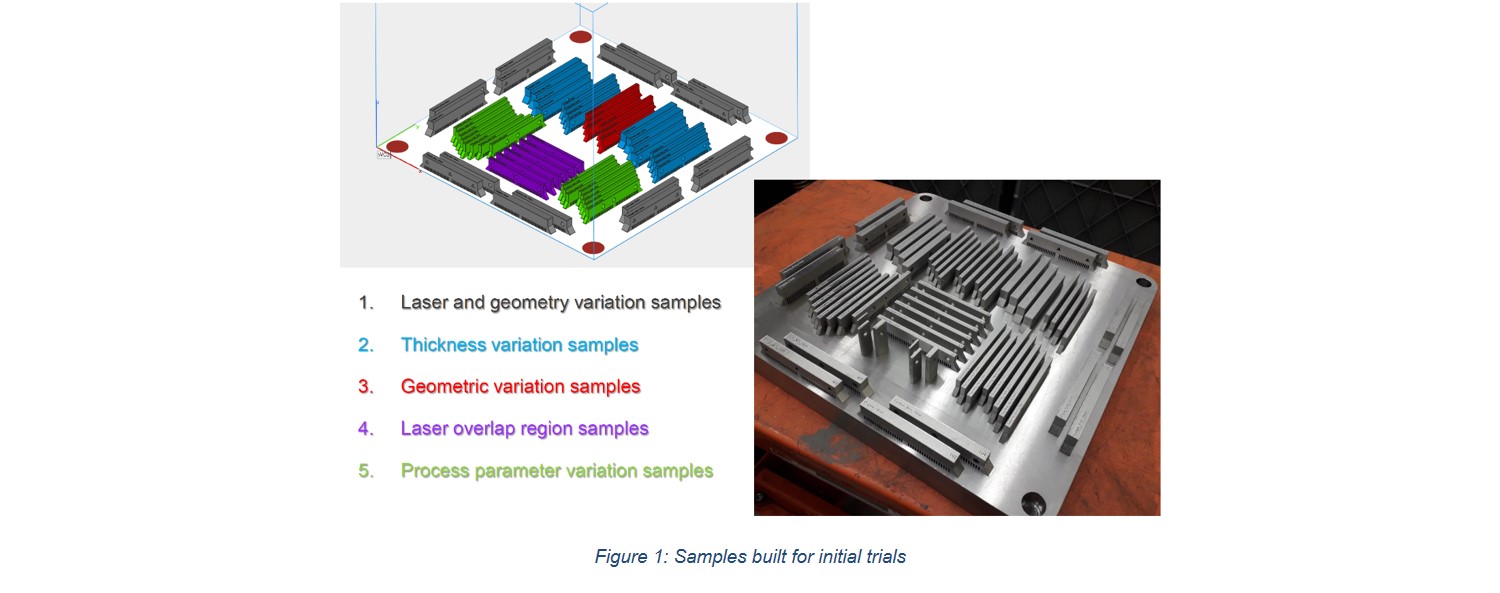

AM process & materials used |

Laser powder bed fusion (In718) |

Laser powder bed fusion AM has a unique thermal cycle that involves a steep thermal gradient up to the materials’ melting point, rapid solidification, and then re-melting on subsequent layers. This causes residual stress to build up in the part which is a significant issue given its effect on distortion, reduced performance and premature failure of the part. This CRP project:

If you are a member you can access the deliverables of this project here.