|

CRP year |

2014 |

|

Budget |

£83k |

|

Project Reference No. |

30522 |

|

Technical Lead |

Justin Dunleavey |

|

AM process & materials used |

Powder bed fusion: electron beam (Ti64), laser (In738) |

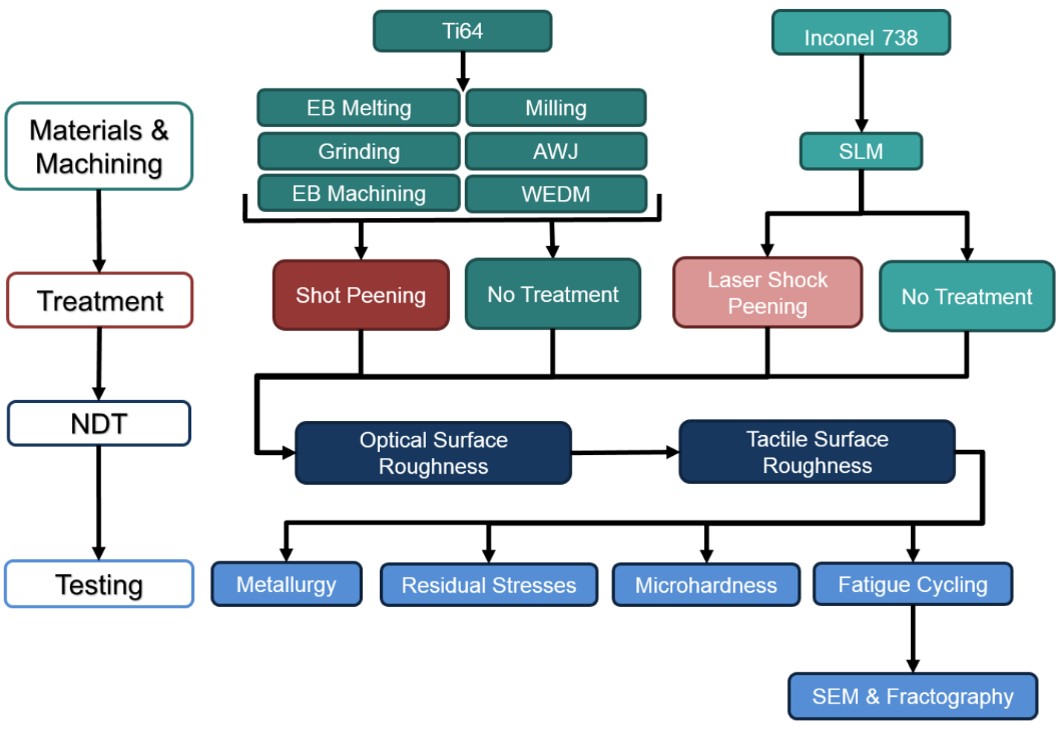

This project examined the effect of post-processing techniques carried out on components produced using a variety of technologies. This work was carried out in order to address issues that exist regarding the surface integrity of parts produced by non-conventional or additive means (key areas – residual stress, fatigue life, surface integrity).

The MTC performed a comprehensive literature review on the influence of component manufacturing method on surface integrity, and existing post-processing techniques employed by industry. This was followed by the completion of experimental work as prescribed in the design of experiments.

If you are a member you can access the deliverables of this project here.