Powder Sensitivity of AM – Phase 2

|

CRP year

|

2018

|

|

Budget

|

£200k

|

|

Project Reference No.

|

32801

|

|

Technical Lead

|

Steven Hall

|

|

AM process & materials used

|

Powder bed fusion: laser (Ti64, In718)

|

Summary

The project was split into two main activities:

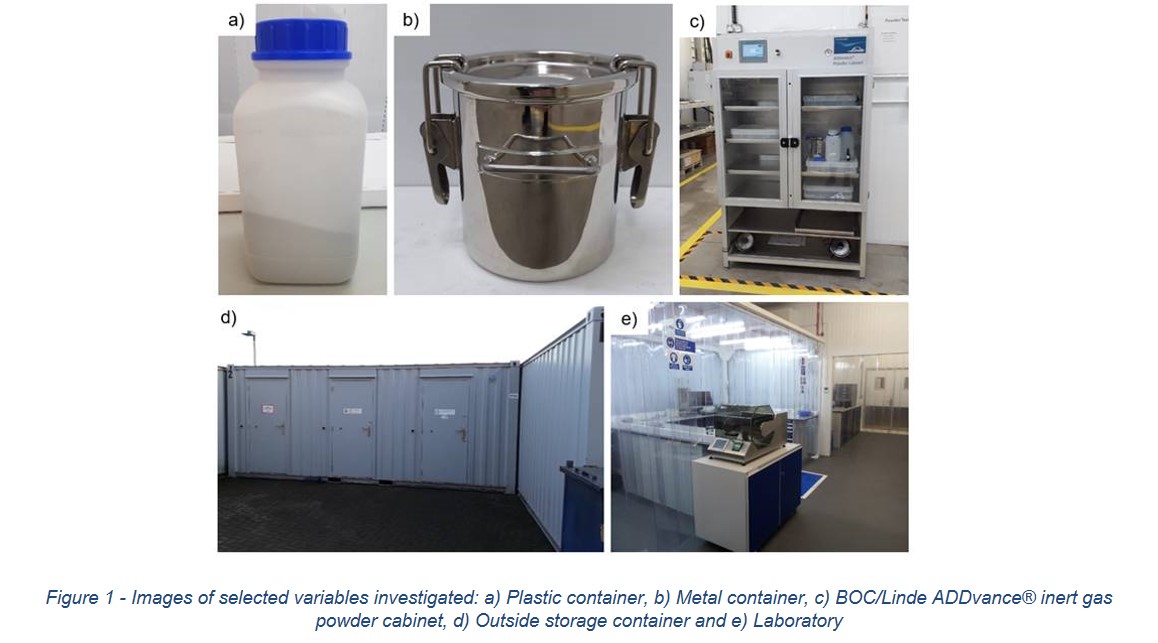

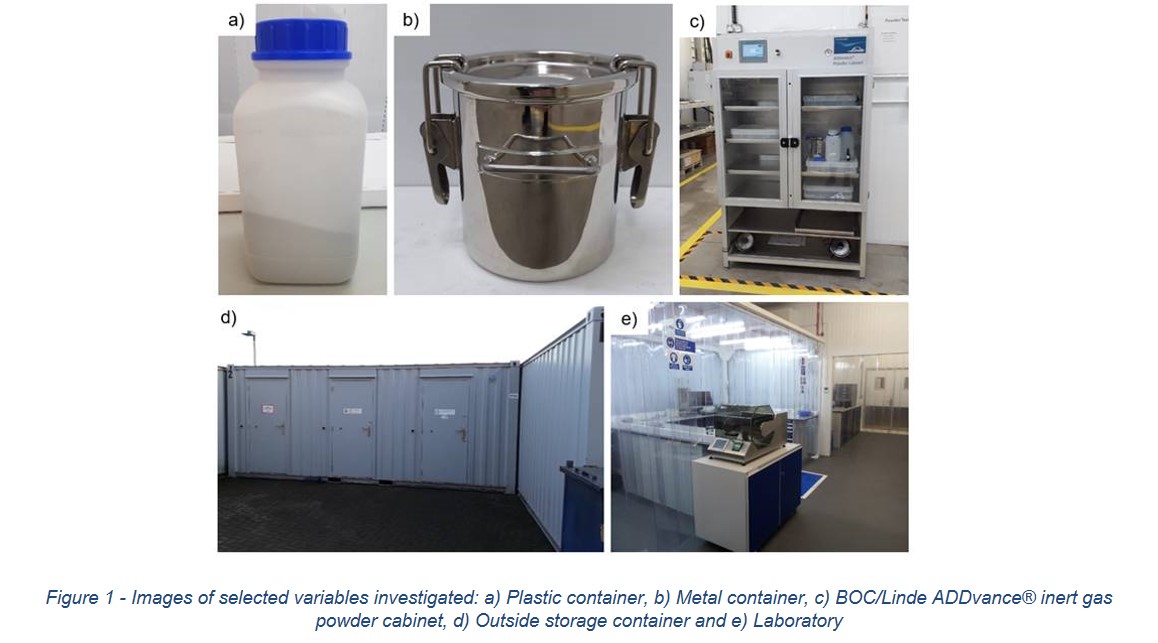

1. Powder storage conditions

- The effect different storage conditions (containers and environments) had on the properties of metal powders and AM parts were assessed.

- The materials investigated were Ti64, In718 and AlSi7Mg over a period of 8 months of storage, with validation confirmed using Ti64 in laser powder bed fusion.

- A survey collating the typical metal powder handling practices and workflows of MTC members was performed to establish best practice procedures.

2. Nitrogen gas utilisation

- Continuing on the work of the phase 1 project from 2016, this work package further explored the effect of using different inert gas atomisation techniques by investigating the effect of the presence of nitrogen in powder, and in the laser powder bed fusion machine on AM part properties.

- A literature review examining the effects of production environment on AM nickel alloys was performed.

DELIVERABLES

If you are a member you can access the deliverables of this project here.