Qtr4 2017 – Qtr1 2019

The objective of this project was to allow an optimised piece of inspection hardware and an enhanced piece of data analysis software to be efficiently used for three forms of inspection relevant to the quality control of additively manufactured parts: integrity, dimensional conformance and surface topology assessment.

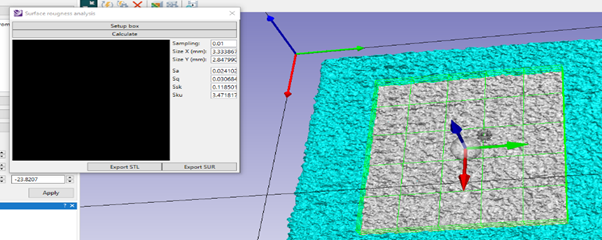

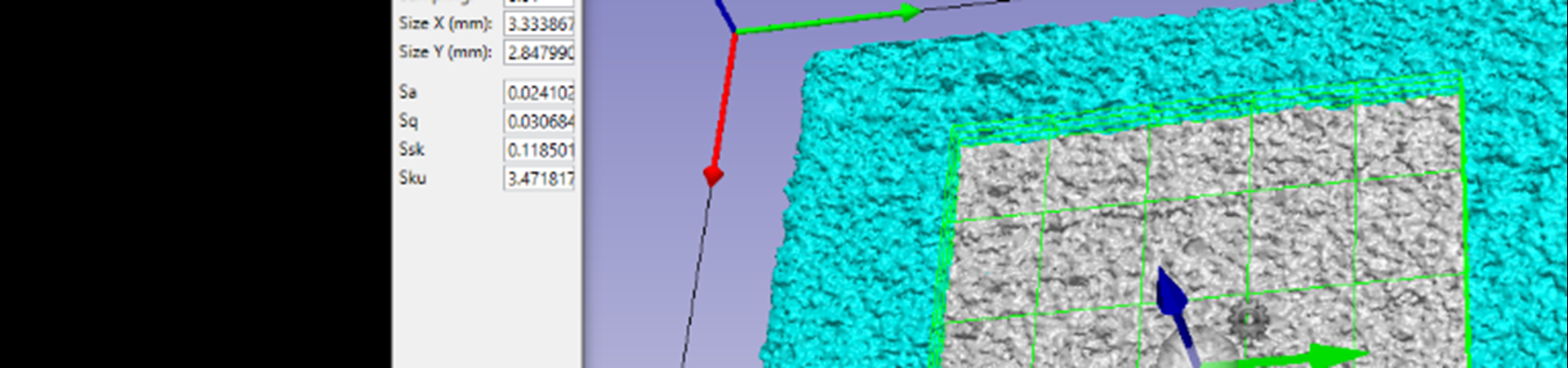

Given that X-ray Computed Tomography (XCT) is already frequently used for integrity and dimensional inspections, the focus was on expanding the capabilities of the hardware and software to surface topology. The project explored hardware improvements to allow the system to better acquire data for this application, and embedded in an XCT data analysis software package the capability to extract surface topology parameters from the scan data.

The new analysis software functionality developed in the project provides a unique capability for the streamlined extraction of surface topology parameters from XCT data.

This is valuable for the assessment surfaces of inaccessible internal features, including in the context of tuning additive build parameters to give specific surface properties or developing finishing methods for internal features.

The MTC conceived the project and coordinated the bid. During the project, the MTC was primarily responsible for coordinating the industrial advisory group and identifying the user requirements, as well as testing and then demonstrating the tools developed. In practice, the MTC also contributed to a range of other partners’ deliverables, by maintaining the focus on the project vision, providing feedback on progress and supporting programme management.