Powder spreadability definition and measurement methodologies

Objective:

Define standardized spreadability parameters which meet the requirements of the PBF process and understand the suitability of the available powder test methods.

Problem:

- Good understanding of powder spreadability is essential to ensure that metal powder can be made to spread well in powder bed fusion (PBF) machines.

- It is not clear whether existing ASTM standard and non-standard test methods for powder flowability adequately capture the requirement for spreadability in PBF.

- Understanding how spreadability effects process performance and part quality is limited and exacerbated by the wide range of PBF machine designs available.

Impact

- This project will address the following gap in the AMSC roadmap – ‘PM2: Spreadability’.

- Ultimately, this will enable AM users to optimise the powder-process property relationship for PBF.

Solution

- Define standardised spreadability parameters which meet the requirements of the PBF process and understand the suitability of available powder test methods.

- Understand what good spreading powder means in terms of process performance and part quality so that spreadability limits can be set.

Output

- WK71393 - Additive Manufacturing of Metals - Feedstock materials - Guide for Assessment of Powder Spreadability

Figure 1: Spreadability project workflow

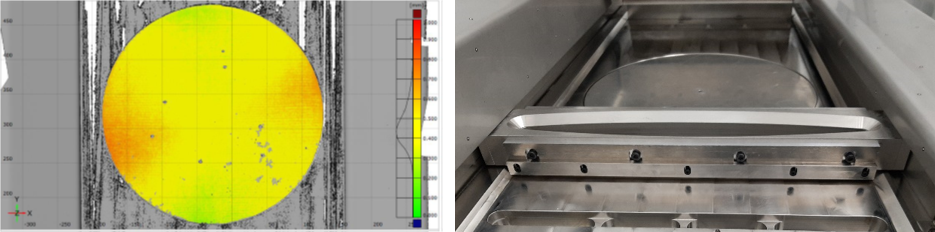

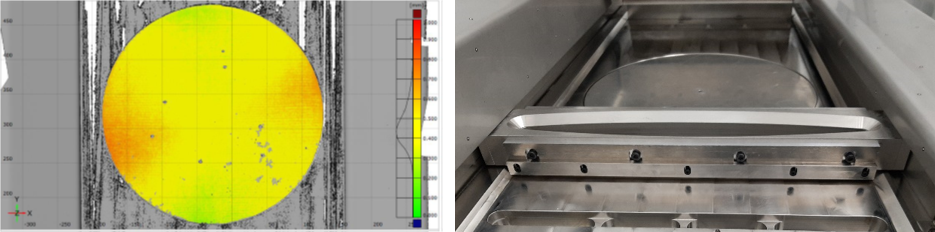

Figure 2: Surface topology image (left) and image of the test bed (right)