Design guide for post-processing of laser powder bed fusion AM components

Objective:

Develop a specific guidance on how to design a component to ensure it can be effectively post-processed.

Problem:

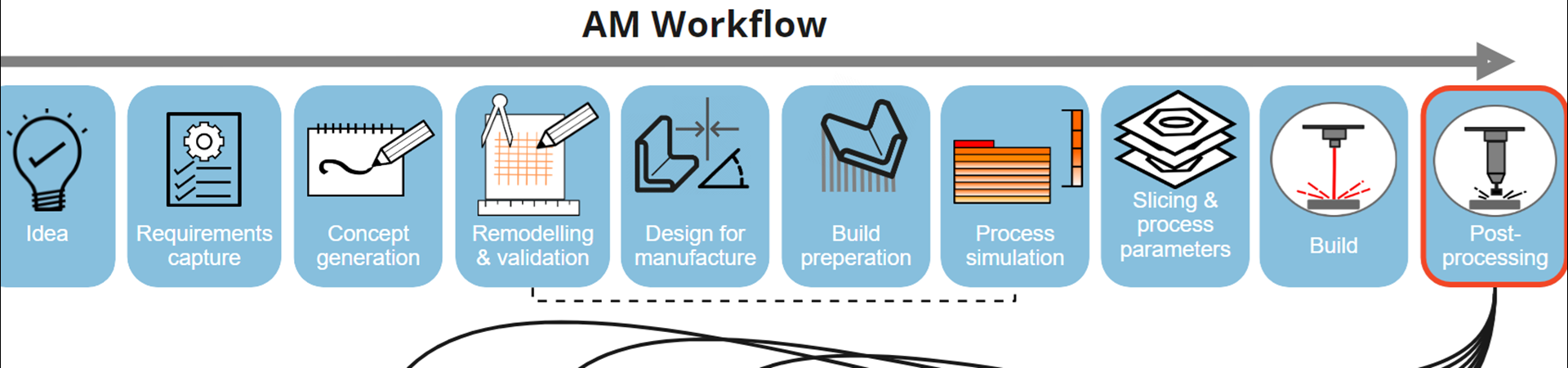

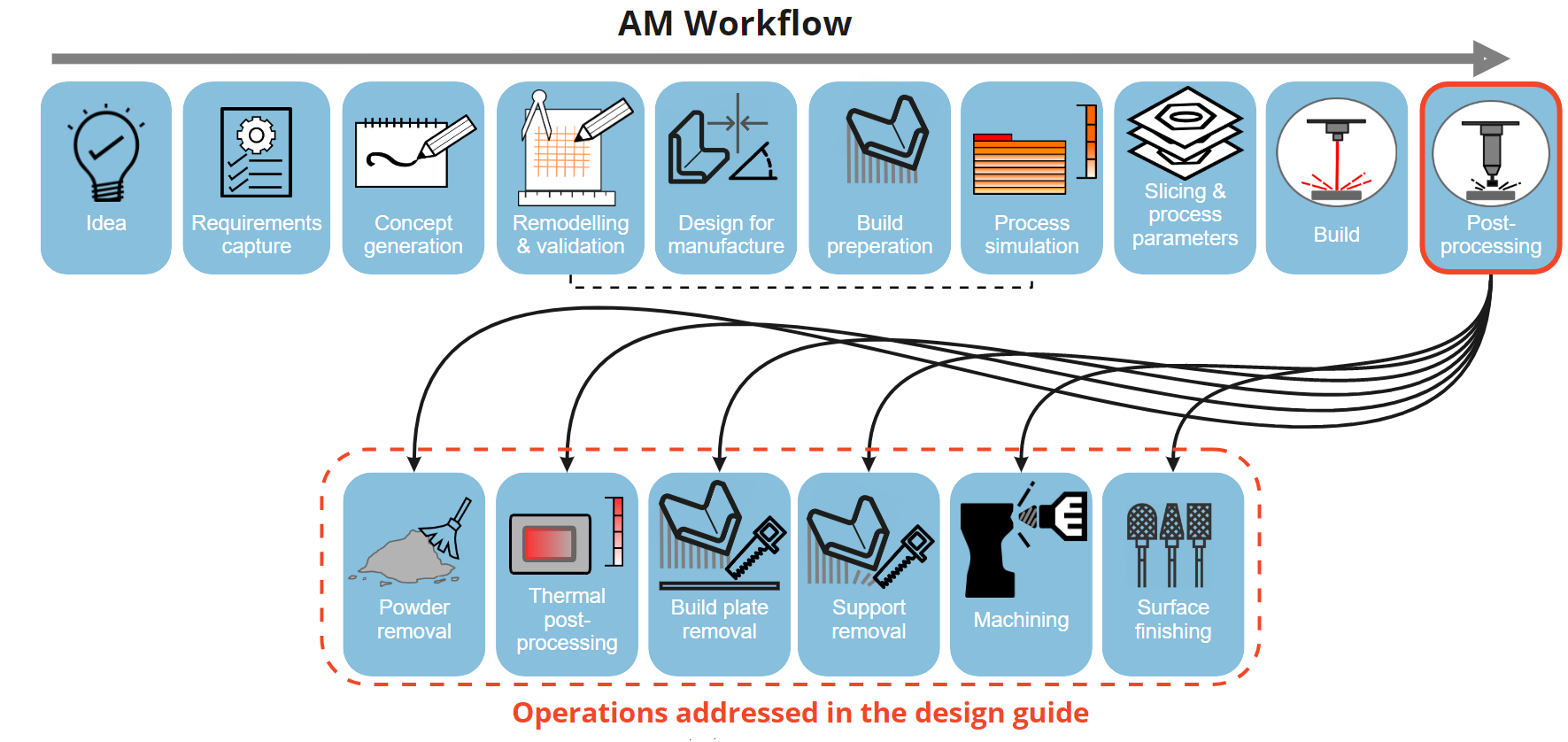

- Good AM design requires consideration of the entire AM manufacturing process chain, including post-processing operations (see Figure 1).

- In spite of the rapidly growing interest from the industry in laser powder-bed fusion for metals, currently, there is a lack of guidance of how and why post-processing is carried leading to inefficient designs, expensive post-processing, high non-conformity and scrap rates.

Impact:

- Specific guidance on how to design a component to ensure it can be effectively post-processed to address AMSC roadmap gap D7: Design Guide for Post-processing.

Solution:

- The proposed solution is a guide that addresses the chain of post-processing operations for metal laser powder bed fusion (PBF-LB/M) and present design considerations, for each type of post-processing operation.

- Topics include:

- An explanation of the most common post-processing steps used in metal L-PBF method and why they are used

- Challenges in carrying out each post-processing operation

- Addressing challenges by design

Output:

- ASTM WK73444 New Guide for Additive Manufacturing Design Post Processing for Metal PBF-LB

Figure 1: AM workflow detailing typical stages and those in scope of this guide