Swiftool Precision Engineering Ltd (SPE) is part of the SPE Group and is a first choice vendor to a global customer base supplying safety critical parts to the nuclear, petrochemical, aerospace and more recently medical markets. The company specialises in supplying high integrity precision machined components, kits and assemblies for applications where high regulation and quality is non-negotiable. SPE has been following the developments in additive manufacturing (AM) for some time, but has hitherto, not seen any appropriate opportunities in its principal markets of nuclear and oil and gas to make investing time and resource an immediate priority. However, in recent times there has been increasing interest in the benefits which AM might bring to these markets, and also to SPEs aerospace business. The challenge facing SPE has been to understand the different AM technologies available and gather first-hand experience on their capabilities and limitations in a measured and impartial way, which does not require costly and potentially ill-advised, investment up front. Hence, for SPE, the DRAMA Programme Support Package opportunities were perfectly timed to improve the company’s readiness to bring AM into its manufacturing portfolio.

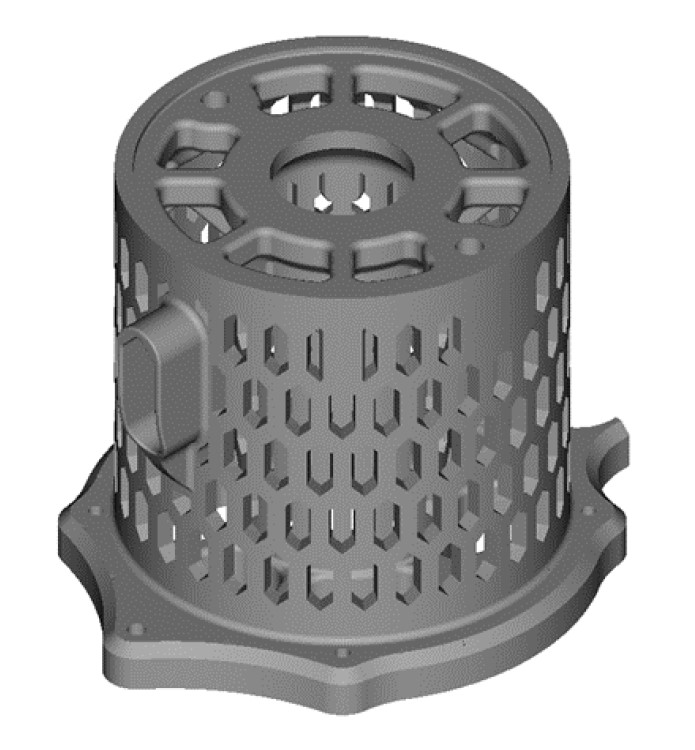

In the first Product Suitability support package, a meeting was arranged between NCAM and SPE engineers to assess the current SPE product portfolio for potential AM candidate parts. The rotation collar shown was selected as being the most suitable, as this component is currently made in several pieces from stainless steel 316L and requires welding operations to join the parts. NCAM engineers looked at all aspects of the technical feasibility and commercial suitability of building the rotation collar using AM and concluded that it was both feasible and suitable as a test piece for trials, although its size would restrict it to a limited number of larger capacity AM machines. Following completion of this work the design authority for the component unexpectedly introduced a re-designed rotation collar which was to prove an even better prospect for AM.

The above investigation paved the way for a second support package, Process Selection, during which NCAM engineers, working closely with SPE, used a structured method to down-select the most suitable metal AM process, based on SPE-specific component specifications and commercial drivers. Laser Powder Bed Fusion (PBF-LB) was highlighted as the most suitable AM process, however, NCAM recommended a number of design changes to improve buildability. These included:

After completing a Manufacturing Readiness Review, a prototype rotation collar was built by Renishaw on an AM500Q LPBF machine, together with a number of material test coupons. Some issues were experienced including banding around the diameter and some build plate deformation due to the large size of the build. Following further design changes, a second build showed improvement in these defects, although some further development work was recommended, should the part proceed to production. Regular review meetings throughout this work helped ensure the effective transfer of AM knowledge to SPE engineers.

"The DRAMA programme has taken SPE’s strategic AM commitment to the next level. In 2020 we completed the first stage of our metal AM ambition through the programme and also invested in our first 3DM machine. The market appetite for metal AM parts is increasing - SPE are a lot closer to being “match ready” on our plan for future metal AM capability thanks to the project."

Sam Handley, Director, Swiftool Precision Engineering

First design for AM

First build of rotation collar