Dec 2017 – Mar 2019

In CONFIGURE a flexible automated repair unit, encompassing every stage of the repair operation (damage assessment, repair, finishing and final inspection) was developed and demonstrated.

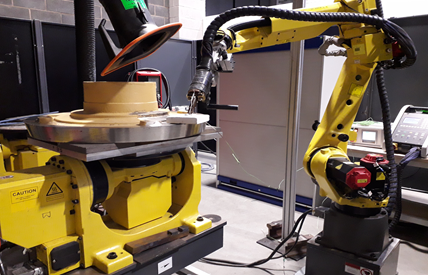

An array of sensors were incorporated into the repair unit to provide both process and part quality data. This information, used to enable the unit to operate in an autonomous mode, was also logged to allow detailed analysis to be performed and provide traceability. Using a robotic platform with interchangeable inspection, deposition and machining heads it allowed parts of almost unlimited size to be repaired in a seamless operation. The new unit, provided in portable and even mobile configuration, enabled it to be positioned wherever required. Two industry case studies, from the mineral extraction and rail sector, were used to demonstrated the effectiveness of the equipment.

The robotic repair cell enables automated remanufacture of complex engineering parts thus reducing the cost, time and variability of the process. In addition, the new approach helps to eliminate hazards to operators including; noise, fumes and vibration which can have serious long-term health implications.