Qtr1 2014 – Qtr3 2016

The objectives of the ANVIL project were to develop a standard approach to AM performance capability assessment and comparison, and to develop innovative design software.

ANVIL addressed the need for the development of a standard approach to AM, specifically metal powder bed fusion performance capability assessment and comparison. No suitable standards or comparisons existed making it difficult for industry to adopt AM The project developed a standard benchmarking approach applicable to all metal powder fusion machines and is relevant to a wide range of end-user sectors. The approach was used to benchmark the latest commercially available machines and the information generated used to form the basis of a “design-for-AM” guide. Work was also carried out in this project to create an AM factory simulation model using discrete element modelling techniques.

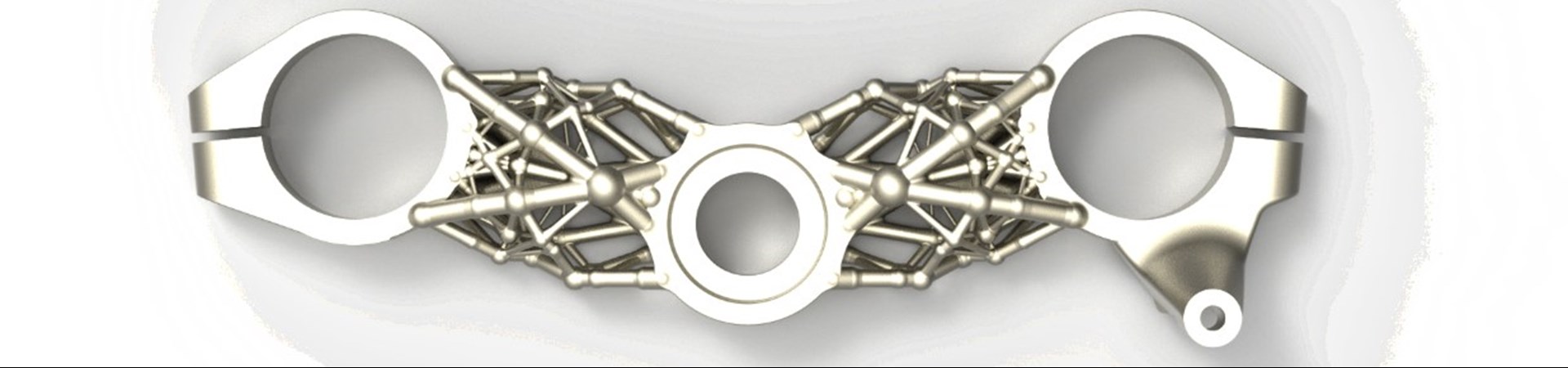

Application demonstrators across aerospace, space, medical and motorsport sectors were redesigned to provide case studies for promoting the effective use of AM technology.

The MTC led the work to define the machine benchmarking by designing artefact parts which were manufactured by the MTC (as well as other institutions) and were measured to establish the performance capability of the machines. MTC created a design guide based on this information. MTC also devised a production readiness assessment methodology to evaluate how robust the AM equipment was, and created the AM factory simulation model for a range of scenarios to match the production volumes of the demonstrators.