|

CRP year |

2019 |

|

Budget |

£37k |

|

Project Reference No. |

33778-12 |

|

Technical Lead |

Helen Terry |

|

AM process & materials used |

Laser powder bed fusion, Ti64 using Renishaw AM500Q |

This project aimed to demonstrate the accuracy and efficiency of predicting the temperature and microstructure (phase changes) in an additively manufactured (laser powder bed fusion) specimen using an analytical model as a solution to overcome multiscale difficulties in traditional thermal modelling of AM build simulations. This improvement is against conventional finite element based analysis that are computationally expensive and inherently slow.

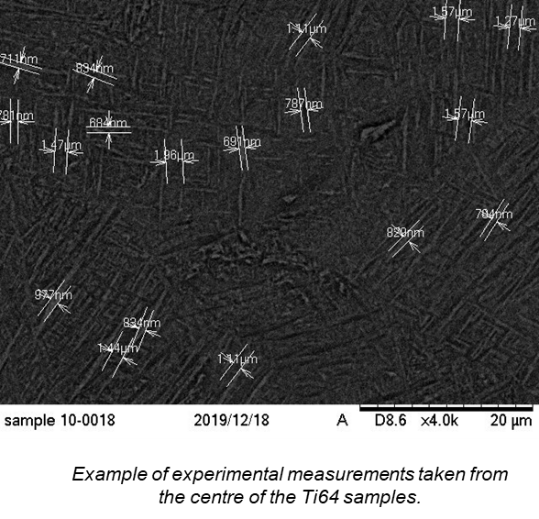

The project utilised the output of the thermal model to predict the phase changes and lamellae thickness in an industrially relevant alloy, which was Ti64. The capability was also used to investigate the influence of the laser power on these two material characteristics and indicators of quality, such a defects from lack of fusion, effectively showcasing the use of the capability for process parameter development.

The outcomes of the project concluded successful implemented of the thermal model with the addition of boundary conditions (considering geometry edges) and accessing GPU computing by re-writing the code, further reducing the computational time of the capability. The code has been coupled with the microstructure model and predicts lamellae thickness well, with verification and validation completed through microscopy imaging and experimental measurements.

If you are a member you can access the deliverables of this project here.