|

CRP year |

2016 |

|

Budget |

£40k |

|

Project Reference No. |

31494 |

|

Technical Lead |

Mikdam Jamal |

|

AM process & materials used |

Powder bed fusion, laser (SS316L) |

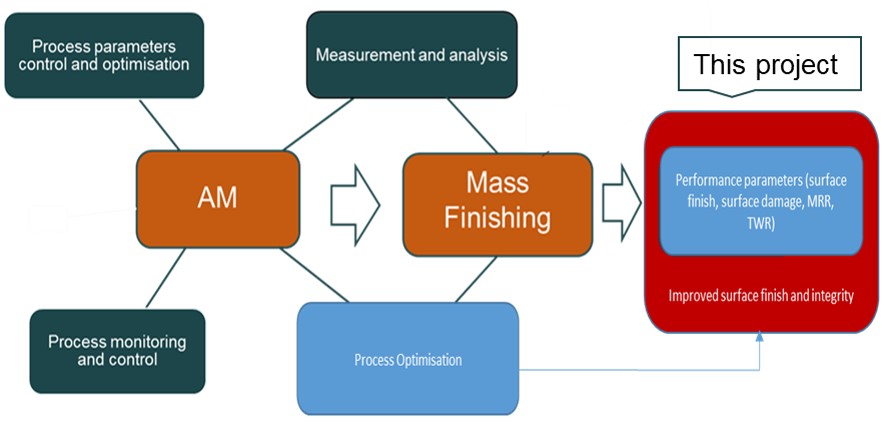

Surface finish of a metal AM part is uneven, with surface roughness being variable over the facets of the design. Furthermore, the surface quality achievable using standard post-processing methods is generally unacceptable for wider AM part uptake in some major industrial processes. The objectives of this project were to:

If you are a member you can access the deliverables of this project here.