The National Centre for Additive Manufacturing (NCAM) has launched the latest round of internal funding for its Additive Manufacturing (AM) teams to build internal capability in cutting edge AM research. This year, the AM build team have specifically focused their funding on three areas of interest: sustainable AM, accelerating the maturity of emerging AM materials and enabling new process adoption and development. Each year, the MTC invests in its staff to ensure they are at the cutting edge of their technology fields. This year is no different and our teams are poised to tackle industrial and national challenges such as achieving Net Zero. In the coming weeks, additional NCAM research topics on laser DED, materials development, and NDT will be released.

At its core, AM is a sustainable technology, creating near net shapes with minimal waste products. NCAM wants to be at the forefront of enhancing the sustainable credentials of AM. Our research will be looking to further our large format AM capability through understanding and adopting material and processes which enable parts that are made via Large Format Additive Manufacturing (LFAM), to be recycled or reused to minimise waste. In addition to this, topics such as better understanding powder reuse before scrappage will be investigated. In parallel with this, the teams will be looking at ways to improve part lifespan performance and, therefore, reduce wastage through the introduction of coatings to improve the performance of polymer parts (such as hydrophobic coating for polymer tooling). Finally, a state-of-the-art review will be undertaken, looking into the latest sustainable materials within the AM market and this will go on to shape our technology roadmap for future years to come.

Materials are at the heart of any AM process and NCAM has been working hard to develop cutting edge material capability, which enable applications in Space, Power & Energy (Electrification & Nuclear), Defence and Aerospace. Our Metal Powder Bed Fusion (MPBF) team will be undertaking a streamlining process to further enhance our material development processes and procedures. This research will refine the methods that are used to establish new process parameters for emerging materials. This refinement will go on to reduce the time and risk of developing such parameters. The MPBF team will also be developing work on high strength aluminium materials such as A20X. The Polymer team will support a growing industry demand through investigating high performance materials for tooling, assessing parameters, such as aging, environmental factors, and anisotropy. This is in addition to further work on understanding which materials provide the optimal performance for LFAM. Finally, the teams will look into material property control and multi-material applications/processes. Establishing a state-of-the-art review which will go on to inform our future strategic decision making.

The teams at NCAM continue to work with the latest equipment to understand the limits of these processes. This year's funding will further our understanding and experience using the latest AM equipment, de-risking the process for companies and partners looking to use this technology in the future. This year NCAM will further its skills investment into Ceramic AM through funding research programmes across both our newly acquired Xjet and Photocentric systems. Our Polymer team, working closely with our Design for Additive Manufacturing team, who are together pushing the boundaries of what is possible with our Carbon M2 system. Our Bind & Sinter team are rapidly upskilling on the use of our newly acquired AIM3D system, which enables extremely cost efficient AM parts through material extrusion AM using injection moulding metal materials.

The findings for this research will go on to power our continued work to accelerate the adoption of AM in the UK and beyond. Although it’s not possible to share all of the findings in a public forum, the team at NCAM are available to discuss similar topics. To find out more, please contact us at ncam@the-mtc.org.

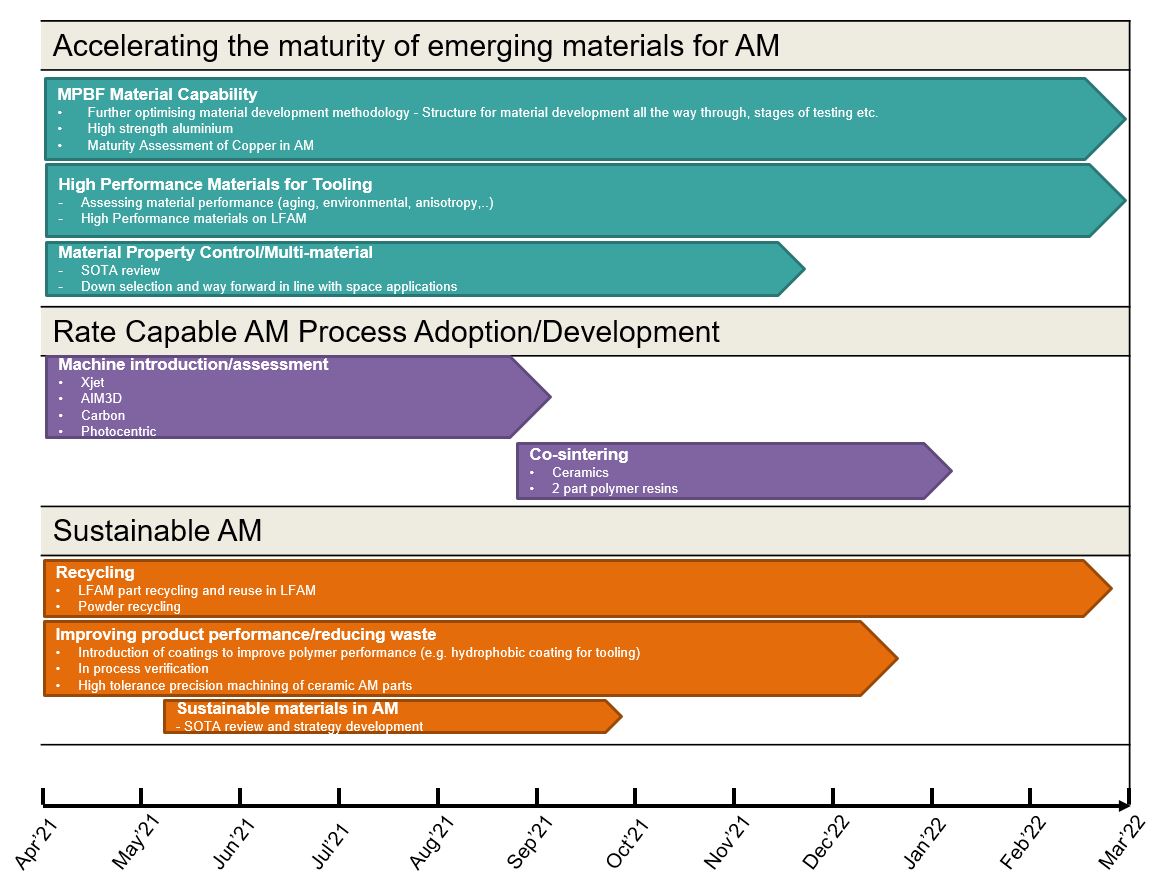

Figure 1: Top level overview of NCAM AM internal research topics

Share this page: