May 2016 - Aug 2018

The objective of this project was to develop a completely new generation of Electron Beam Melting (EBM) AM machines which addressed the critical challenges identified for current generation machines, namely:

The intention was that the EBM machine should be suitable for the production of “flying” production parts

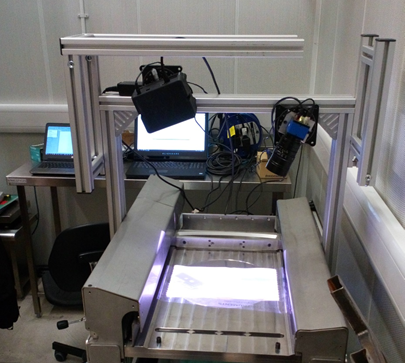

The new Scanning Electron AM (SEAM) system being developed in the RAMP-UP project represents a significant step change in technology and performance, employing key innovations which systematically and comprehensively address the limitations of the current EBM technology to give a process which is faster, easier to use, more reliable and able to produce higher quality parts. Key innovations included: Precise powder deposition; Active charge neutralisation; In-process inspection of layer and melt quality.

MTCs activity within the project was to develop a next generation powder deposition mechanism for an EBM machine which: