Qtr2 2015 – Qtr4 2019

Metal powders are widely used within net-shape and additive manufacturing (NS&AM) processes for sectors such as aerospace and automotive. As metal powders are primarily produced outside the UK, a UK-based supply chain is needed to service growing market demand.

Liberty Speciality Steels (LSS) an experienced manufacturer of highly engineered steels decided to expand its capabilities into steel and nickel powder production and sought MTCs support to achieve this ambition.

Through the CASCADE programme, LSS and MTC have worked collaboratively with seven other partners to develop a range of technologies across the metal powder supply chain. Supported by Finance Birmingham via and AMSCI fund, CASCADE has enabled LSS to establish its first powder production facility.

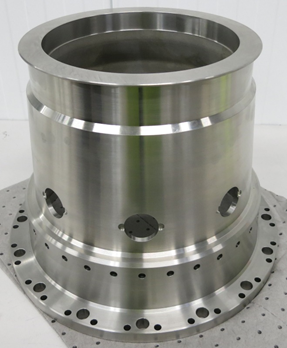

Successful completion of the project has enabled Liberty to acquire a vacuum induction melting (VIM) gas atomiser with an anti-satellite system, capable of producing highly spherical steel and nickel powders with minimum amount of satellites and improved flowability, making them ideal powders for AM. LPM has also developed the capability to handle and package powders under inert atmosphere to reduce moisture and improve powder performance.

MTC has supported LSS in developing powders by providing access to world-leading capabilities, including state-of-the-art powder characterisation labs, industrial-scale hot-isostatic pressing (HIP) and metal-injection moulding (MIM) facilities.