|

CRP year |

2015 |

|

Budget |

£95k |

|

Project Reference No. |

30640 |

|

Technical Lead |

Nick Brierley |

|

AM process & materials used |

N/A |

To address the very demanding inspection requirements, CT is increasingly being deployed in industry, both for integrity and dimensional conformance assessment. However, CT inspections are typically associated with slow inspection times, high costs, extremely large data volumes to analyse and store, and greater limitations on what components can be inspected than conventional, 2D, radiography. So far, for a general and challenging inspection problem, there are no radiographic inspection options that do not involve a significant trade-off, but efforts are being made to tackle these, for instance focused on speeding-up CT scans. This project sought to improve the available trade-offs of 2D radiography. A Phase 2 project on this topic was also carried out.

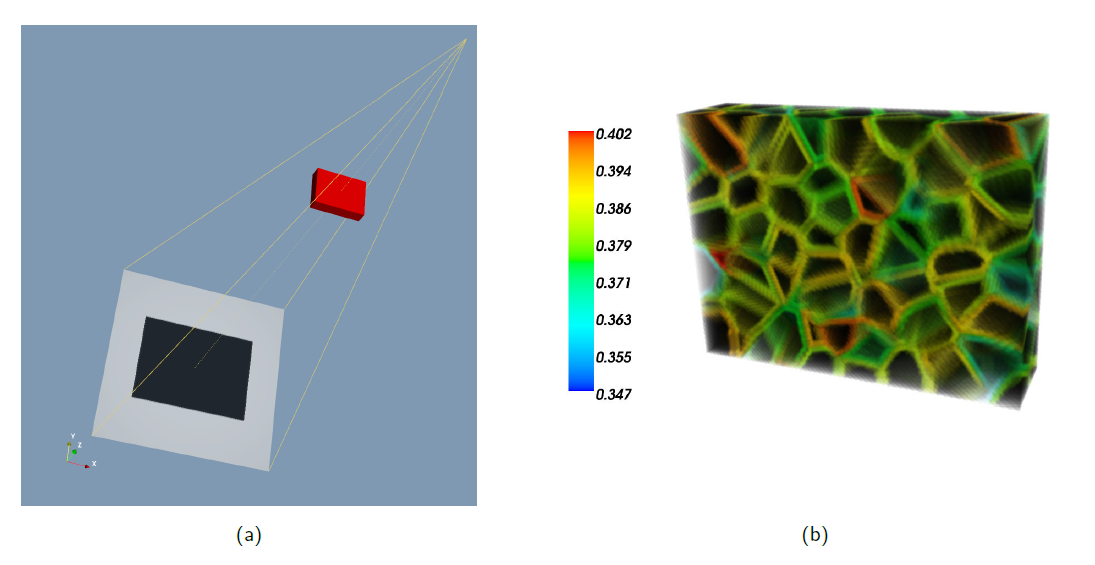

Figure 1: The pre-optimisation state: on the left the configuration in aRTist is presented, on the right a rendering of the associated detectability map is shown. The colour scale is based on the detectability metric computed for the sampled defects. The blotchy appearance is a consequence of nearest-neighbour interpolation between the 200 defect samples applied.

If you are a member you can access the deliverables of this project here.