|

CRP year |

2016 |

|

Budget |

£100k |

|

Project Reference No. |

31514 |

|

Technical Lead |

Bochuan Liu |

|

AM process & materials used |

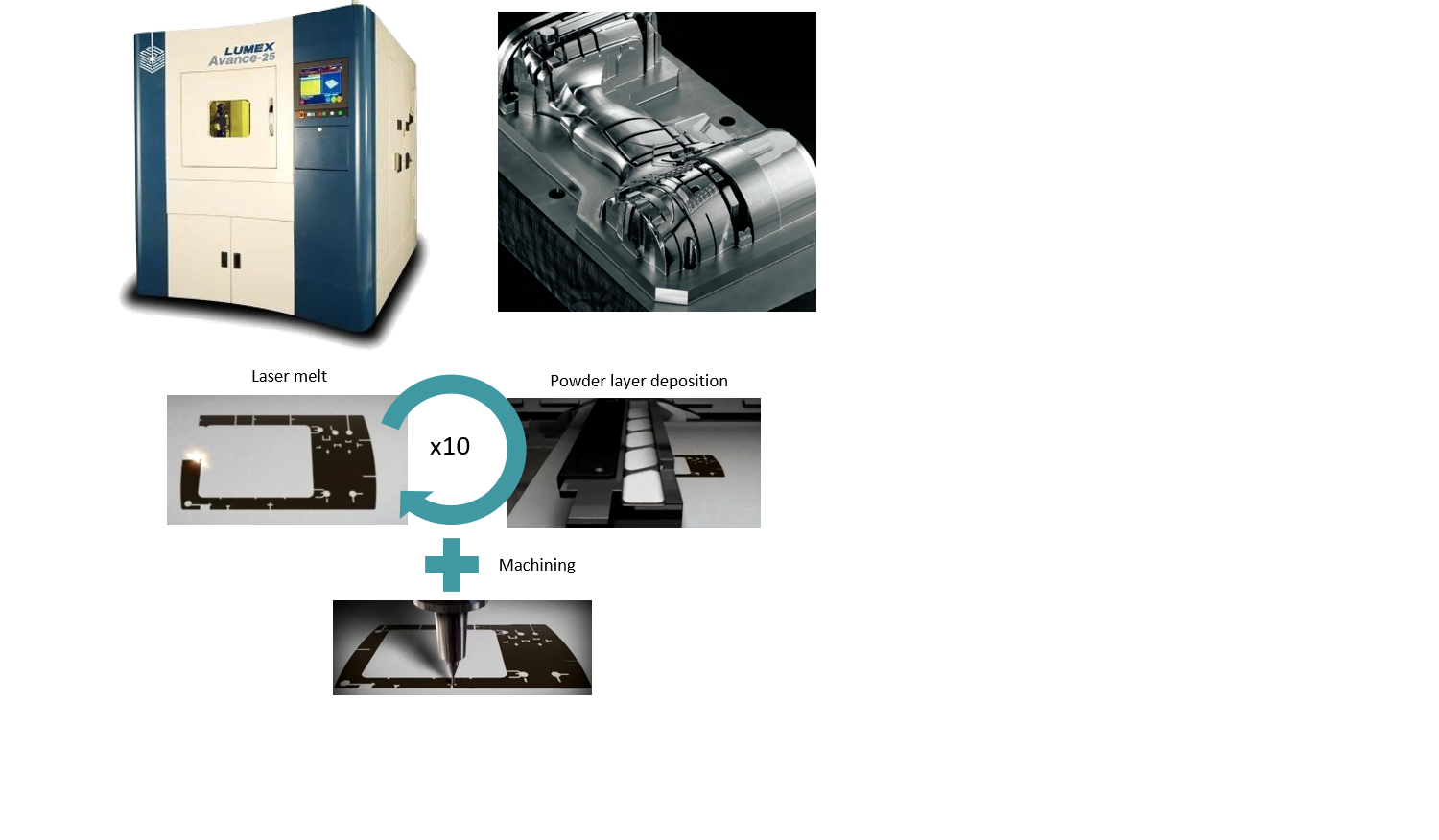

Hybrid laser powder bed fusion, In718 |

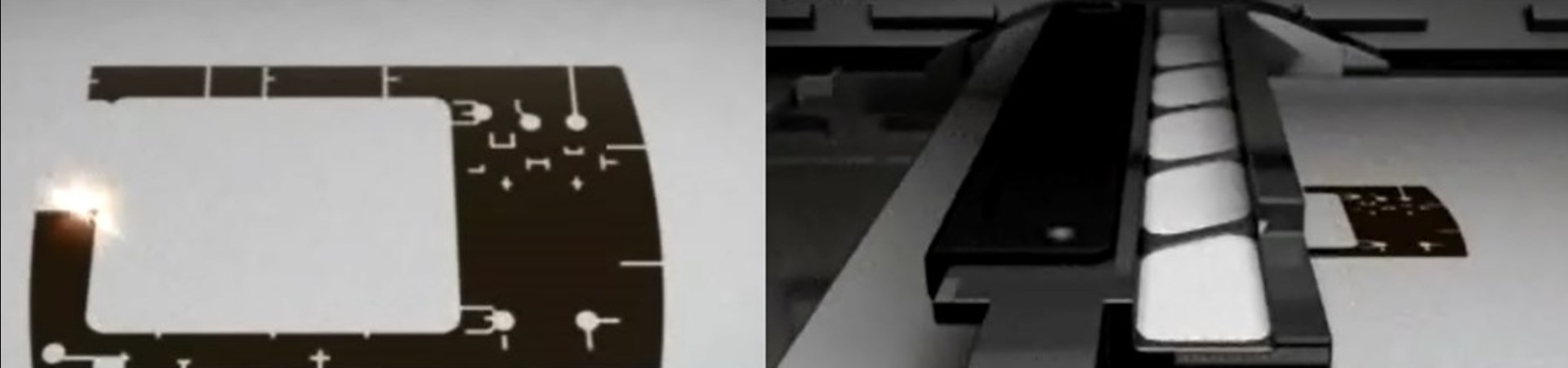

In hybrid AM additive and subtractive processes are combined, in principle enabling the benefits of AM, including geometrical and production freedom to be combined with the accuracy and productivity of machining. In the case of the Matsuura Lumex Avance 25 machine, laser powder bed fusion is combined with 3-axis milling enabling upward facing surfaces and some downward facing surfaces (moderate overhangs) to be machined during the build process.

The process was developed primarily for the production of complex mould inserts and this CRP project investigated the capabilities and limitations of this system for end-use parts (as an alternative application to tooling) with particular focus on the following areas:

If you are a member you can access the deliverables of this project here.