|

CRP year |

2012 |

|

Budget |

£100k |

|

Project Reference No. |

21718 |

|

Technical Lead |

Andrew Triantaphyllou |

|

AM process & materials used |

Laser powder bed fusion (AlSi7Mg0.6, In718) |

This CRP project was conceived with the aim of comparing the performance latest generation of high performance selective laser melting (SLM) machines (also known as laser powder bed fusion) against one another.

The initial idea was to employ Ti64 (a standard build material) for this comparison, however, following discussions with the MTC members who are active in the project it was decided to re-scope the project, focusing on two materials (aluminium alloy L169 and nickel alloy Inconel 718). Because of this change, it was not possible to evaluate an extensive range of equipment originally envisaged and so trials focussed on a single commercial machine, the EOS M280 offering higher laser power and layer thickness compared to its predecessor. One trial evaluated the M280 by developing a material parameter set for a new material, AlSi7Mg0.6. The second trial assessed the improvement in deposition speed of the newer machine using In718 and any effect on part quality.

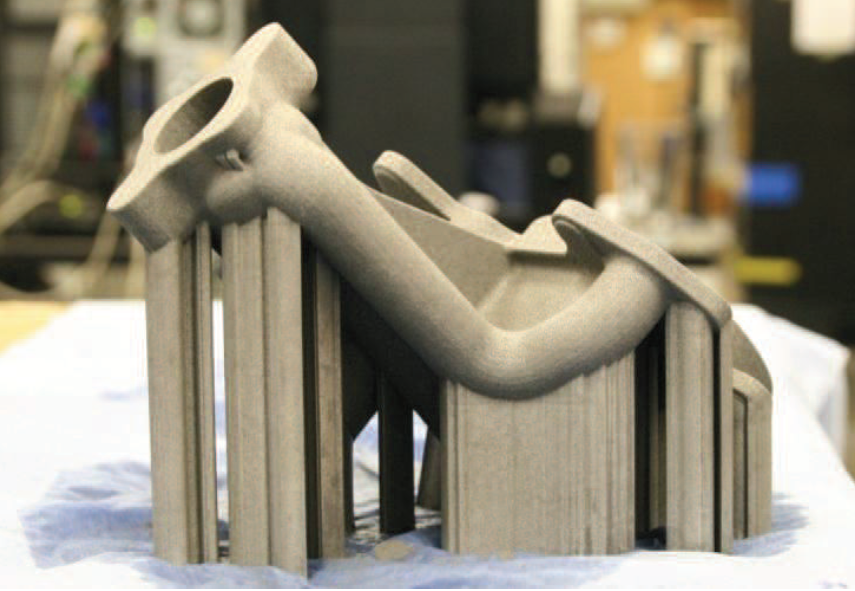

Figure 1: A part built to evaluate deposition rate on an example realistic geometry with supports

If you are a member you can access the deliverables of this project here.