|

CRP year |

2020 |

|

Budget |

£50k |

|

Project Reference No. |

34745-11 |

|

Technical Lead |

Mikdam Jamal |

|

AM process & materials used |

Metal binder jetting (SS316L) |

This project will deliver unique and transformative empirical models to allow an additive manufacturing (AM) process, which is dependent on the control of numerous parameters each having variable effect, to be designed to perform at or near an optimal set of conditions without extensive and expensive prior testing, for the efficient production and optimisation of AM component.

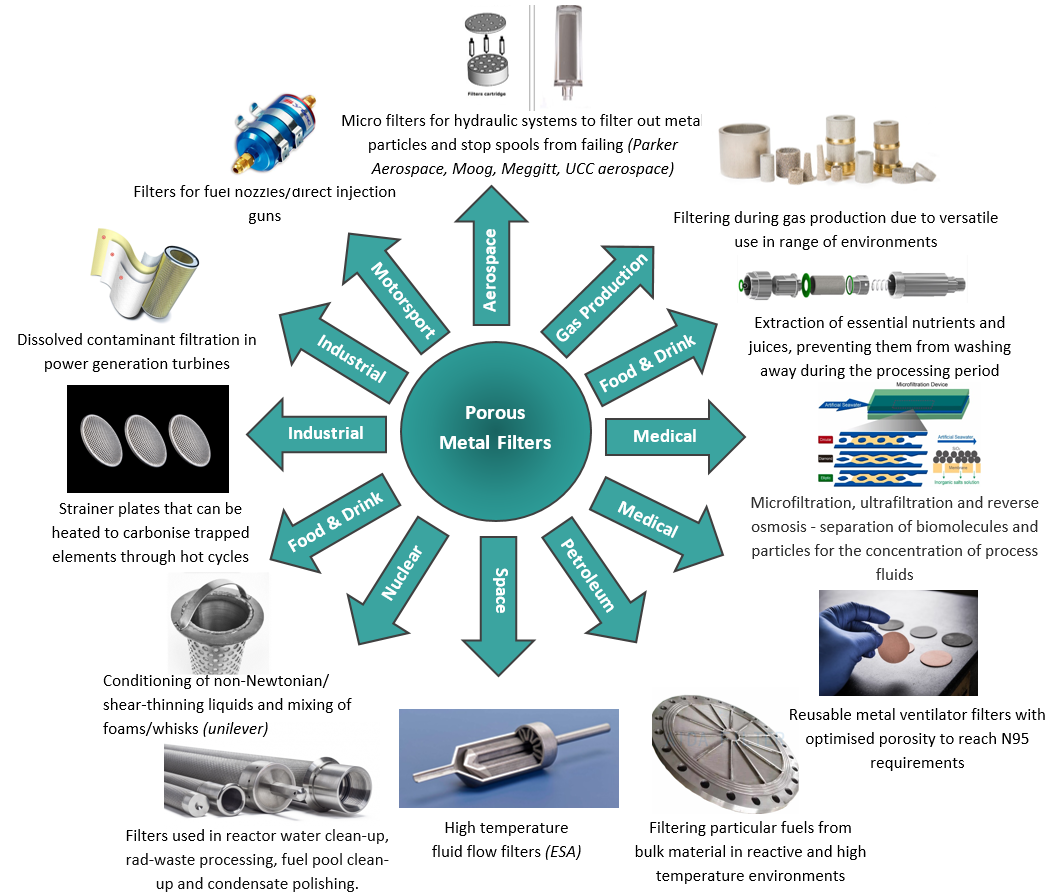

The optimisation of metal binder jetting (MBJ), a high throughput metal AM production process, has been chosen as a case study for this project. The objective of manufacturing functionally-graded high value components (such as porous structures shown in the figure) is being used to define and evaluate the approach.

The following work packages outline the project:

WP1: Literature review on state-of-the-art of MBJ optimisation

WP2: Design of test artefacts and experimental set-up for empirical MBJ processing

WP3: Develop process optimisation algorithms to generate empirical equation sets.

WP4: Implementation, evaluation, and validation of multi-objective optimisation.

If you are a member you can access the deliverables of this project here.