|

CRP year |

2019 |

|

Budget |

£39k |

|

Project Reference No. |

33778-16 |

|

Technical Lead |

Reza Nekouie Esfahani |

|

AM process & materials used |

Fused deposition modelling (FDM) - Fortus 450mc. High-performance flame-retardant thermoplastic polymer ULTEM™ 9085. |

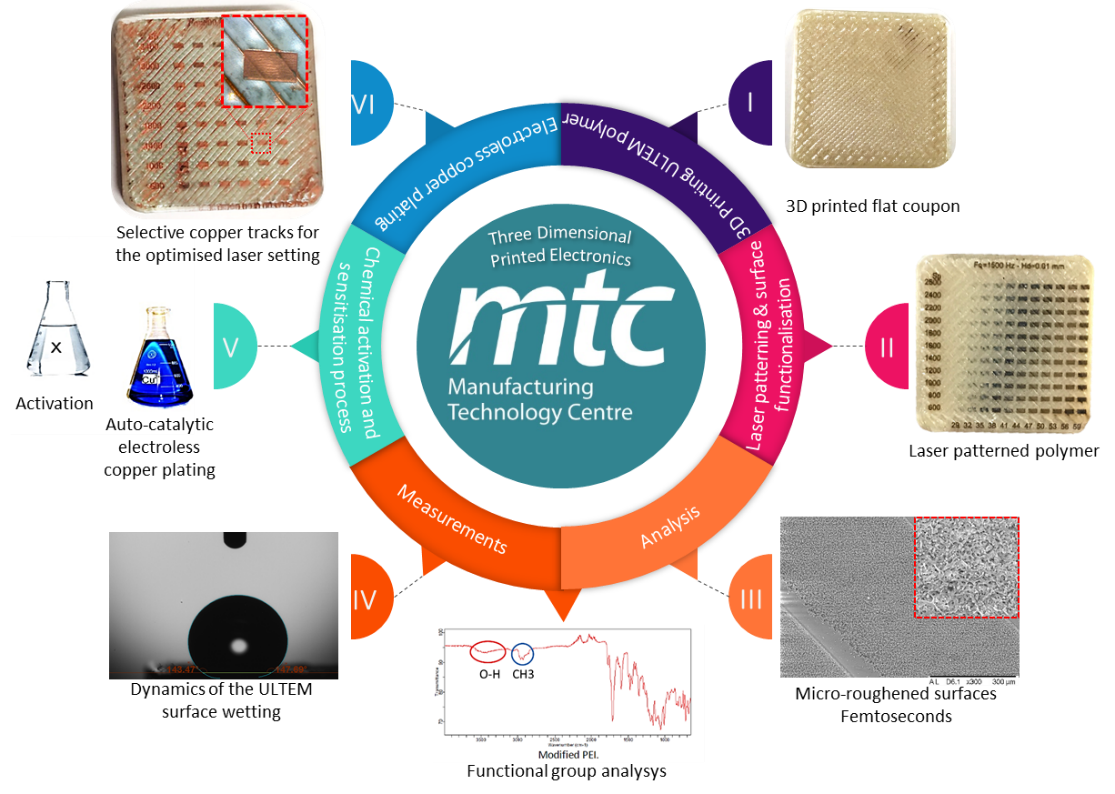

Conventional manufacturing of electronic systems have limited design freedom and customisation. This project looked at developing a new technique for integrating electronic circuits into the complex geometry of 3D printed polymers via laser patterning, chemical activation and an electroless plating process. This enables AM to address current issues in electronics manufacturing and achieve the required functionality, miniaturisation and reliability for modern electronic systems.

The objectives of this project were to:

If you are a member you can access the deliverables of this project here.